Description

Looking for a reliable way to produce fresh, high-quality pineapple juice? Our pineapple juice machine delivers powerful, stable performance for continuous juice extraction. Using an advanced screw press system, it efficiently extracts juice from pineapples, apples, tomatoes, ginger, wheatgrass, and other fruits and vegetables. Available in models with or without a crusher and with processing capacities from 0.5 to 2.5 tons per hour, it’s the ideal choice for commercial and industrial uses. Below are the specifications for reference:

Specifications of Pineapple Juicer Machine

| Series | Model | Capacity | Power | Dimensions (mm) |

|---|---|---|---|---|

| LZ (Without Crusher) Designed for pre-cut pineapples and other fruits or vegetables | LZ-0.5 | 0.5 t/h | 1.5 kW | 910×385×810 |

| LZ-1.5 | 1.5 t/h | 4.0 kW | 1,300×500×1,330 | |

| LZ-2.5 | 2.5 t/h | 11 kW | 1,480×740×1,780 | |

| PZJ (With Crusher) Complete crushing, juicing, and residue discharge in one machine | PZJ-0.5 | 0.5 t/h | 2.05 kW | 910×500×1,250 |

| PZJ-1.5 | 1.5 t/h | 6.5 kW | 1,300×650×1,380 | |

| PZJ-2.5 | 2.5 t/h | 12.5 kW | 1,500×700×2,000 |

Wide Applications

- Fruit Juicing: Pineapple, apple, pear, mulberry, grape, etc.

- Vegetable Juicing: Tomato, ginger, celery, carrot, spinach, wheatgrass, etc.

- Other Materials: Herbal and plant extracts for medicinal or flavoring use.

Features and Advantages

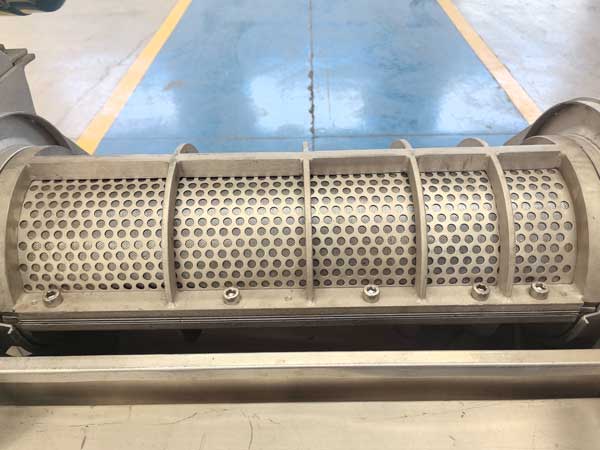

- Screw Design for High Efficiency: Our pineapple juice machine adopts a single screw combined with a filter screen as its core components. During operation, the screw continuously pushes and compresses the material, efficiently separating juice and residue. The juice yield can reach 60%-80%. Besides, the single-screw design make the machine structurally simple and easy to maintain.

- Stainless Steel Construction: All parts that come into contact with the material are made of high-strength stainless steel, offering excellent durability, hygiene, and easy cleaning.

- Cold Pressing for Nutrient Retention: Operating at low rotational speed, the cold press juicer reduces oxidation and heat buildup during extraction. This helps retain vitamins, enzymes, and natural aromas, producing fresh, high-quality juice with a rich taste.

Wide Applications: This juicer machine is highly versatile, which can handle hard fruits such as apples and pears, soft fruits like grapes and strawberries, and vegetables including carrots, tomatoes, ginger, and celery.

Pineapple Juice Production Line

Our industrial pineapple juice production line is designed for high efficiency, superior juice quality, and food safety, making it ideal for commercial juice manufacturers.

1. Raw Material Selection

- Only fresh, ripe pineapples without rot or pest damage are selected. Ideal maturity ranges from 80% to 100%.

- Purpose: Ensures consistent flavor, aroma, and juice quality.

2. Washing

- Pineapples are washed thoroughly with clean water to remove surface contaminants and dirt.

- Purpose: Protects fruit quality and prevents contamination during processing.

- Equipment: brush washing machine and air bubble washing machine.

3. Peeling

- The pineapple peel is carefully peeled off, because pineapple peel contains proteases and tannins, which can affect juice quality.

- Purpose: Prevents enzymatic or tannin-related degradation of juice flavor and ensures high-quality product.

- Equipment: Pineapple peeling machine; Coring machine (optional).

4. Crushing and Juice Extraction

- Equipment: Hammer crusher, to crush pineapple flesh to 5–8 mm particle size.

- Advantage: Efficiently breaks down fruit cells, improving juice yield and efficiency.

- Screw Press Juicer: Automatic screw pressing extracts juice with >75% yield.

- Advantage: Maximizes juice extraction while minimizing pulp waste, improving output and economic efficiency.

- For small-scale production, you can choose PZJ series juicer machine (with built-in crusher.)

5. Filtration:

- Coarse filtration removes large fibers and debris.

- Fine filtration is performed using a 0.5 mm plate filter or a centrifugal filter to remove fine fibers and suspended particles.

- Purpose: Produces clear juice with minimal solids, stable color, and better mouthfeel.

6. Degassing

- Vacuum degassing removes dissolved oxygen and air.

- Protects natural pigments, vitamin C, and aroma.

7. Sterilization

- Juice is sterilized using flash pasteurization through a heat exchanger.

- Purpose: Ensures microbiological safety while preserving flavor and nutrients.

What Fuxun Machinery Can Offer

Fuxun Machinery is a trusted manufacturer and supplier of industrial pineapple juice machines and complete pineapple juice production lines. We offer equipment from fruit washing, peeling, and crushing to juicing and even filling. Whether you need a single pineapple juicer machine or a fully automated juice production line, Fuxun offers customized solutions and technical support. Just contact us today to discuss your projects!