Description

A peanut butter production line is a complete processing system used to convert raw peanuts into smooth or crunchy peanut butter. It typically includes roasting, cooling, peeling, grinding, and mixing processes.

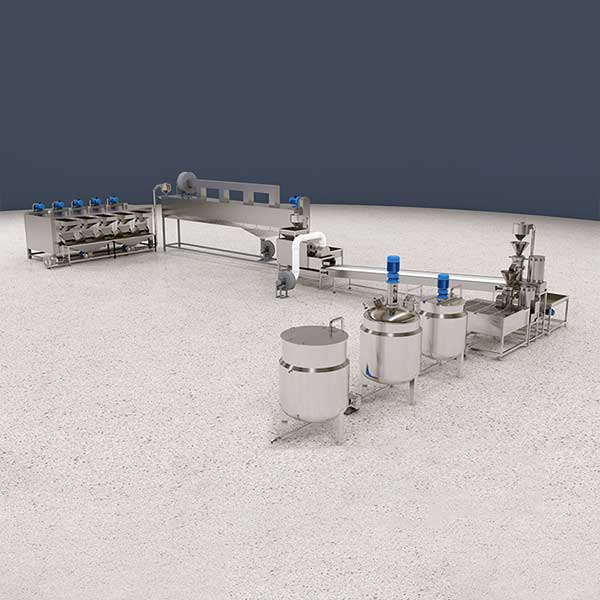

At Fuxun Machinery, we don’t just sell individual machines —we design complete peanut butter production lines that help manufacturers produce stable peanut butter from day one. We offer a range of equipment, including peanut roasters, peeling machines, colloid grinders, storage tanks, and mixing tanks, with different capacities and automation levels.

Our production line is ideal for:

- Peanut butter startups planning 100-500 kg/h production;

- Medium factories (300-600 kg/h) upgrading from semi- or manual processing

- Industrial manufacturers requiring 1-3 tons/hour continuous output

- Producers of smooth or crunchy peanut butter, as well as tahini, almond butter, and other nut pastes.

Production Capacity & Configuration

- Processing Capacity: 100 kg/h – 3,000 kg/h

- Production Mode: Batch or Continuous

- Automation Level: Semi-automatic to fully automatic

- Customization: Layout, capacity, material, process flow, and equipment tailored to your factory.

👉 You don’t need to adapt your factory to our machines. We design the whole peanut butter production line to fit your space, budget, and production goals.

Peanut Butter Production Process

Fusion Machinery has rich experience in offering peanut processing equipment. Here let’s overview each stage of the peanut butter making process.

- Peanut Roasting: Roasting is crucial for enhancing the flavor and aroma of peanuts. However, if roasted improperly, peanuts can become too bitter or overcooked. Therefore, it is essential to control the temperature carefully.

- Cooling: After roasting, peanuts need to be rapidly cooled to preserve their quality and prepare them for peeling. The cooling process prevents overcooking and stabilizes the peanut’s texture.

- Peeling: This step involves removing the peanut skins to ensure a smooth texture and high-quality peanut butter.

- Grinding: Once peeled, the peanuts are ground into a smooth paste. The grinding process is critical for making peanut butter.

- Mixing: After grinding, the peanut paste is mixed with other ingredients, such as oil, salt, and sometimes sugar, to enhance flavor and texture.

- Cooling & Degassing: Improves stability and shelf life of the peanut butter.

👉 Note: Not every customer needs all steps. The production line can be simplified or expanded based on your actual requirements.

Peanut Butter Production Equipment

We offer two different peanut butter production line systems:

- Batch Production Line (taking 200 kg/h for example): Ideal for small to medium-sized businesses requiring flexibility and variety in production.

- Continuous Production Line (taking 1000 kg/h for example): Perfect for large-scale manufacturers, providing high-capacity, continuous production to meet demand in high-volume markets.

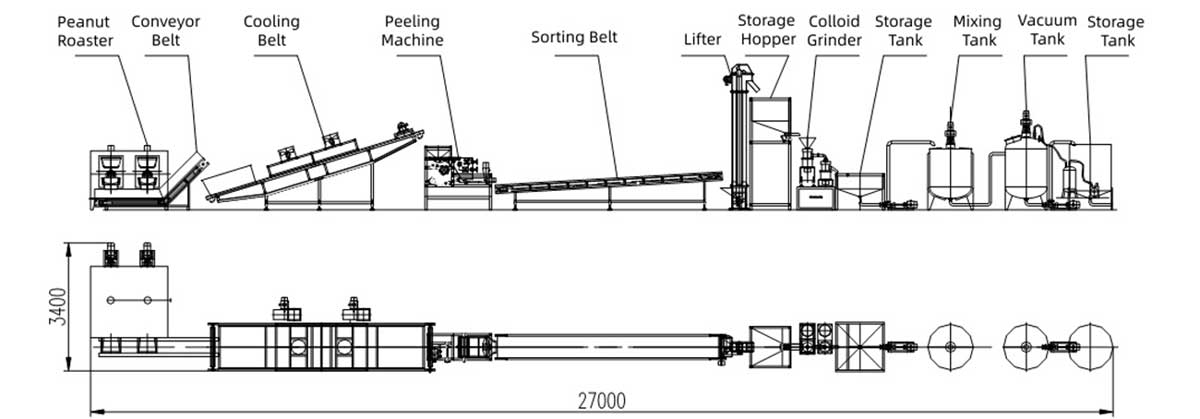

200 kg/h Batch Peanut Butter Production Line

| No. | Equipment | Power (kW) | Dimensions (mm) | Quantity | Function |

|---|---|---|---|---|---|

| 1 | Drum Roaster | 2.2 + 45 | 2,900×2,100×1,750 | 1 | Roasts peanuts evenly, enhancing flavor and texture. |

| 2 | Conveyor Belt | 0.75 | 3,000x500x900 | 1 | Transports roasted peanuts to cooling belt for efficient processing. |

| 3 | Cooling Belt | 5.6 | 6,000×1,200×1,600 | 1 | Cools roasted peanuts quickly to prevent over-roasting and preserve quality. |

| 4 | Peeling Machine | 3 | 2,000x800x1,650 | 1 | Removes the skins from peanuts for smoother peanut butter. |

| 5 | Dust Removal System | – | 1,000×1,000×3,000 | 1 | Collects red skins and other dust particles (optional). |

| 6 | Sorting Conveyor | 0.75 | 6,000x800x1,000 | 1 | Sorts peanuts, ensuring only the highest quality peanuts are processed. |

| 7 | Lifting Machine | 0.75 | 1,000x500x3,800 | 1 | Elevates peanuts to the necessary height for further processing. |

| 8 | Storage Hopper | 0.05 | 1,200×1,200×3,000 | 1 | Stores peanuts before grinding and mixing. |

| 9 | Peanut Butter Grinder | 11 x 2 | 1,250x550x1,100 | 2 | Processes peanuts into smooth peanut butter. |

| 10 | Storage Tank | – | 200L | 1 | Stores peanut butter before packaging or further processing. |

| 11 | Paste Pump | 1.5×2 | 1,200x300x350 | 2 | Pumps peanut butter efficiently to storage or packaging stations. |

| 12 | Mixing Tank | 2.2 | 300L | 1 | Mixes the peanut butter, ensuring even consistency and texture. |

| 13 | Vacuum Tank | 2.2 + 1.5 | 300L | 1 | Removes air from the peanut butter for a smooth, consistent product. |

| 14 | Control Panel | – | – | 2 | Centralized control system for the entire production line. |

| 15 | Pipeline | – | – | – | Connects various components to ensure smooth operation. |

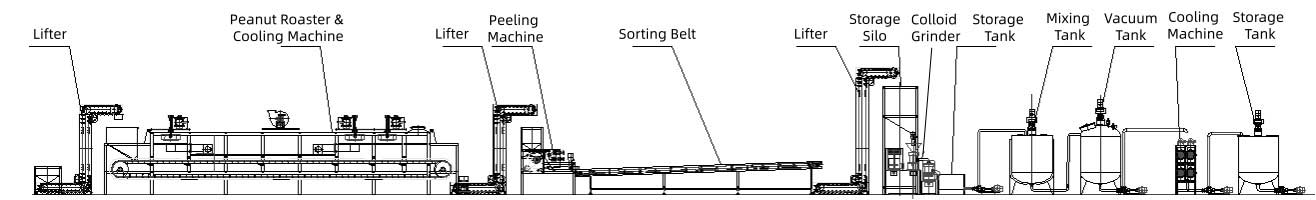

1000 kg/h Continuous Peanut Butter Production Line

| No. | Equipment Name | Power (kW) | Dimensions (mm) | Quantity | Function |

|---|---|---|---|---|---|

| 1 | Automatic Lifter | 0.75 | 2,500x700x3,000 | 1 | Efficiently transports peanuts vertically to roaster, ensuring consistent material flow. |

| 2 | Continuous Roasting Machine | 245 | 11,000×2,100×2,600 | 1 | Uniform peanut roasting, enhancing flavor, aroma, and texture. |

| 3 | Vibrating Machine | 0.75 | 3,000x400x1,200 | 1 | Separates and discharges roasted peanuts efficiently. |

| 4 | Z-shaped Lifter | 0.75 | 2,500x700x3,000 | 1 | Transport the roasted peanuts to peeling machine. |

| 5 | Peeling Machine | 2.2 | 1,900×1,100×1,900 | 1 | Removes peanut skins, improving the final peanut butter texture and taste. |

| 6 | Shakron System | 2.2 | 800x800x3,000 | 1 set | Removes dirt, debris, skins, and any foreign objects from peanuts. |

| 7 | Sorting Belt | 0.75 | 8,000x800x1,000 | 1 | Allows operators to manually or automatically sort peanuts. |

| 8 | Z-shaped Lifter | 0.75 | 2,500x700x4,200 | 1 | Used for vertical transport peanuts for grinding, higher capacity. |

| 9 | Storage Bin | – | 2,500×1,100×3,500 | 1 | Stores processed peanuts temporarily for grinding. |

| 10 | Colloid Grinders | 30×4 | 1,150x500x1,000 | 4 | Grinds peanuts into smooth peanut butter. |

| 11 | Storage Tank | – | 1,000L | 1 | Stores processed peanut butter before packing. |

| 12 | Pump | 3 | 1,200x400x450 | 1 | Transfers peanut butter between tanks. |

| 13 | Mixing Tank | 5.5 | 1,500L | 1 | Mixes peanut butter ingredients evenly. |

| 14 | Vacuum Tank | 8.5 | 1,500L | 1 | Removes air to achieve smooth texture and extend shelf life. |

| 15 | Cooling Machine | 3 | 2,600x800x1,850 | 1 | Cools peanut butter for packaging. |

| 16 | Storage Tank | 3 | 1,500L | 1 | Holds cooled peanut butter for furthing processing. |

| 17 | Control Panel | – | – | 3 | Controls all equipment in the production line, ensuring smooth operation. |

| 18 | Pipeline | – | – | – | Connects the various machines for efficient material flow. |

Operation Requirements

200 kg/h Batch Peanut Butter Production Line

Designed for small to medium-sized producers, this batch line requires about 150 m² of workshop space and can be smoothly operated by 3–4 workers. It is an ideal choice for startups, private-label producers, and businesses looking to expand step by step.

1000 kg/h Continuous Peanut Butter Production Line

Built for large-scale, high-volume production, this continuous line requires approximately 200 m² of factory space and operates with only 4-5 workers, thanks to its high level of automation. It delivers stable output and consistent product quality, making it the preferred solution for industrial peanut butter manufacturers.

Differences Between Batch and Continuous Production Lines

The main difference between the batch and continuous production lines is the peanut roaster. With the continuous belt roasting machine, the production can work non-stop.

| Item | Batch Production Line | Continuous Production Line |

|---|---|---|

| Production Mode | Batch processing | Continuous operation |

| Capacity | Small to medium | Medium- or Large-scale |

| Flexibility | High | Moderate |

| Automation Level | Medium | High |

| Labor Requirement | Low | Low |

| Initial Investment | Lower | Higher |

| Best For | Startups, niche products | Industrial manufacturers |

👉 Not sure which line fits your production plan?

Just contact us with only three things: target capacity, available factory space, and budget range.

Our engineers will: design a suitable process flow; recommend the right equipment and offer you a reasonable price.

👉 Send us your basic requirements and get a customized peanut butter production line solution — free of charge.

Why Choose Fuxun’s Nut Butter Line?

Proven Processing Flow: The basic nut butter line follows a production process:

Roasting → Cooling → Peeling → Grinding → Mixing → Degassing → Cooling → Packaging

This ensures stable texture, controlled oil separation, and long shelf life.- CE-Certified, Food-Grade Peanut Butter Equipment: Fuxun Machinery offers nut roaster, peeling machine, colloid grinder, etc. for peanut butter production. All equipment is CE certified and suitable for international markets.

- Custom Solution: With rich experience and a professional team, we are able to offer a tailored solution according to your requirements. Whether you’re ready to upgrade your existing peanut butter production line or start a new operation, we are here to help.