Description

Fruit pulper machine is an essential piece of equipment in fruit and vegetable processing. It efficiently separates pulp, peel, and seeds to produce smooth pulp — ideal for juice, puree, jam, and sauce production. Fuxun Machinery offers DJ series and MDJ series destoning pulper machines, available in various models with processing capacity from 0.12 to 7.5 tons per hour. All machines are CE certified and made of food-grade stainless steel, ensuring hygienic and durable operation. Below are the main parameters for your reference.

DJ Series Pulping Machine

| Model | Power | Output Capacity | Dimensions (mm) |

|---|---|---|---|

| DJ1-0.12 | 1.5 kW | 0.12 t/h | 820*450*950 |

| DJ1-2.5 | 4 kW | 2.5 t/h | 1450*770*1523 |

| DJ1-3.5 | 5.5 kW | 3.5 t/h | 1550*770*1530 |

| DJ1-5 | 11 kW | 5 t/h | 1750*1000*1700 |

| DJ2-0.24 | 3 kW | 0.24 t/h | 820*1000*1350 |

| DJ2-4 | 7.5 kW | 4 t/h | 1370*1370*1800 |

| DJ2-7.5 | 11 kW | 7.5 t/h | 1935*2275*1700 |

| DJ3-7.5 | 18.5 kW | 7.5 t/h | 1935*2275*1700 |

MDJ Series (Destoning Pulper)

| Model | Power | Output Capacity | Dimensions (mm) |

|---|---|---|---|

| MDJ2-4 | 7.5 kW | 4 t/h (Mango 1.8 t/h) | 1370*1370*1800 |

| MDJ2-5 | 15 kW | 5 t/h (Mango 3 t/h) | 1650*1370*2000 |

The MDJ series fruit pulper is specially designed for stone fruits and hard-seed fruits, performing both destoning and pulping in one continuous process.

Suitable Materials: mango, peach, apricot, plum, and more.

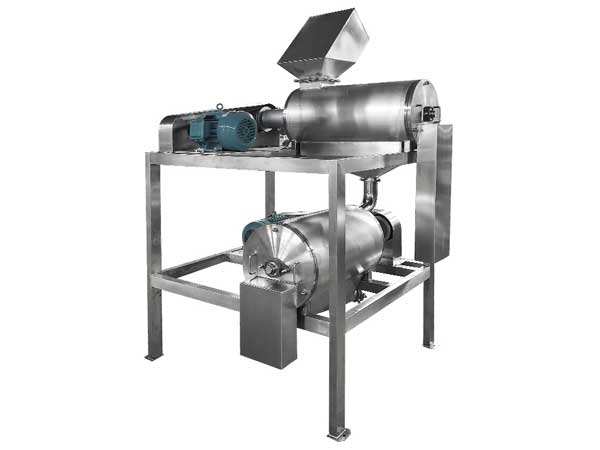

DJ Series Fruit Pulping Machine (Single / Double / Triple Stage)

Fuxun Machinery offers the DJ series in single-stage, double-stage, and triple-stage models to meet different processing needs.

Applicable Materials

- Soft fruits: pre-crushed tomato/kiwi, strawberry, seabuckthorn, grape, etc.

- Hard fruits after pre-cooking and softening: hawthorn, date, apples, pears, and similar fruits.

- Pre-cut vegetables: celery, spinach, chili, and other leafy or fibrous vegetables.

Machine Structure and Working Principle

The DJ series pulping machine is mainly composed of a feeding hopper, juice outlet, residue outlet, cylindrical sieve, pulping blades and scraper, casing, frame, and transmission system.

During operation, the pre-processed fruits or vegetables are fed into the machine through a hopper are evenly spread onto the rotating sieve. Inside the machine, the scraper blades rotate at high speed. Due to the high-speed rotation of the scraper and the spiral advancing angle, the material moves helically along the screen. Under the action of centrifugal force, the pulp and juice are pressed through the screen and collected, while the peel, seeds, and other residues are discharged from the residue outlet. In double-stage or triple-stage models, the process is repeated, further refining the pulp and improving yield.

MDJ Series Destoning Fruit Pulper (Double-Stage)

The MDJ series combines destoning and pulping functions in one continuous process. It is specifically designed for stone fruits and hard-seed fruits that require seed removal before pulping.

Suitable Materials:

- Stone Fruits: Mango, peach, apricot, plum, and similar hard-core fruits.

- Soft & Small-Seed Fruits: Tomato, kiwi, strawberry, grape, apple, pear, hawthorn, jujube (after pre-cooking and softening).

- Vegetables: Celery, chili, spinach, and other leafy or fibrous vegetables (after cutting or softening).

Two-stage structure:

- The first stage removes stones or seeds.

- The second stage refines the pulp and separates peel and residue.

Machine Structure and Working Principle

Includes a feeding hopper, screen cylinders, destoning rotor, scraping blades, pulp and residue outlets, frame, and drive system.

The fruit enters the first stage, where the high-speed rotating destoning rotor breaks and separates the pulp from the seeds. Then centrifugal force pushes the juice and pulp through the screen into the second stage. The second pulping stage refines the pulp further, while seeds, peels, and fibers are automatically discharged through the residue outlet.

Features of Industrial Fruit Pulping Machine

- Automatic Pulp–Residue Separation: Our fruit pulper machine efficiently separates juice and pulp from peels, seeds, and fibers—delivering a high-quality pulp output with minimal waste and maximum efficiency.

- Adjustable Pulp Fineness: The cylindrical screen offers multiple aperture options, while the adjustable blade angle lets you easily control the pulp consistency to your exact production needs—whether you want a coarse, natural texture or a smooth, refined finish.

Hygienic and Durable Construction: All parts in contact with the product and the machine frame are made of SUS304 stainless steel, ensuring hygiene, corrosion resistance, and easy cleaning. Our fruit and vegetable processing equipment is CE-certified to meet your needs.

- Versatile Applications: From soft fruits like tomato, mango, and kiwi to stone fruits such as peach and apple, this machine handles them all with ease. It’s designed for versatility, supporting a broad range of fruit and vegetable processing needs.

- Flexible Integration: Can be used as a standalone machine or integrated into a complete fruit processing line for continuous production. Whatever your setup, it fits right in to boost your productivity and product quality.