How to make high-quality peanut butter on a commercial scale? In this article, we’ll take you inside the industrial peanut butter making process, explaining the role of each stage and the equipment used.

Is Making Peanut Butter Profitable?

Yes. Peanut butter is a profitable business.

According to the latest USDA peanut market report (2025), farmer-stock peanuts sell for $0.6-$1.5 per kg; while the peanut butter wholesale prices vary from $2.5 to $6 per kg. We will get about 0.56–0.64 kg of peanut butter from unshelled peanuts.

Let’s take a JMS-130 colloid mill for example:

- Finished output: 300 kg/hour × 8 hours = 2,400 kg/day

- Raw peanuts required: 2,400 ÷ 0.60 = 4,000 kg

- Raw peanut cost: 4,000 × $1.00 = US$4,000

- Other daily costs (labor, energy, packaging, overhead, etc.): US$1,800

- Total daily cost: 4,000 + 1,800 = US$5,800

- Selling price: $3.50 per kg

- Daily revenue: 2,400 × 3.5 = US$8,400

- Daily gross profit: 8,400 – 5,800 = US$2,600

- Gross margin: ≈ 30%

This example shows that a peanut butter business can achieve high output, predictable costs, and attractive profit margins.

Peanut Butter Production Process

The peanut butter making process follows these steps:

Feeding → Roasting → Cooling → Peeling & Half-Splitting → Cooling → Coarse Grinding → Fine Grinding → Seasoning & Mixing → Cooling → Vacuum Degassing → Storage for Filling or Packaging

How to Make Peanut Butter Step by Step

1. Raw Peanut Feeding

The process starts with feeding peanuts into the roaster. Depending on production scale, you can choose feed manually or automatically using lifters and conveyors. Automatic feeding not only reduces labor but also ensures continuous, efficient production.

Equipment Used: Pneumatic Lifter or Conveyor Belt

2. Roasting

Roasting is the most important stage for increasing the peanut butter’s flavor. Using batch drum roasters or continuous belt roasters, the peanuts are roasted to enhance their nutty taste, golden color, and roasted aroma.

Equipment Used: Peanut Roaster

3. Cooling

Once roasted, peanuts must be cooled quickly to stop the cooking process and prevent over-browning. Cooling machine can quickly lower down the temperature, locking in flavor while maintaining quality.

Equipment Used: Cooling Machine

4. Peeling & Splitting

Remove the thin red skins of peanuts and split the peanuts into halves. This step ensures a smooth texture and clean flavor — peanut skins can make butter taste slightly bitter and affect its appearance. The result is clean, light-colored peanuts, ready for grinding.

Equipment Used: Peanut Peeling and Half-splitting Machine

5. Grinding — From Peanuts to Paste

Grinding is the core of the peanut butter production process. It has two stages:

- Coarse Grinding: Peanuts are crushed into a rough paste.

- Fine Grinding: The paste is refined into a smooth, creamy consistency.

Equipment Used: Colloid Grinder

6. Mixing, Seasoning, Cooling & Vacuum Degassing

At this stage, optional ingredients such as sugar, salt, stabilizers, or flavorings are added. The peanut butter is then cooled and processed under vacuum to remove air bubbles — a crucial step for achieving a silky texture and longer shelf life.

Equipment Used: Mixing or Storage Tanks, Vacuum Tank

7. Storage & Packaging

Finally, the finished peanut butter is transferred to storage tanks before filling and packaging.

Equipment Used in Peanut Butter Manufacturing Line

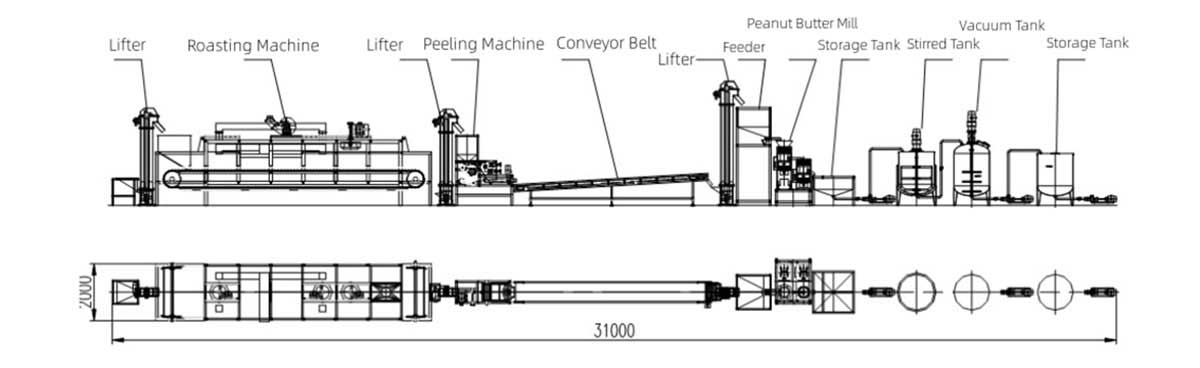

Here is a 500-kg automatic peanut butter production line. Below is a list of the equipment used.

| No. | Equipment Name | Quantity | Power (kW) | Remarks |

| 1 | Stone & Impurity Removal Machine | 1 set | 6.8 | Includes cyclone dust collector |

| 2 | Roasting Machine | 1 unit | 94.5 | Material contact: stainless steel. |

| 3 | Peanut Lifter | 1 unit | 0.75 | PVC/Stainless Steel |

| 4 | Cooling Belt | 1 unit | 1.1+0.55*5 | Material contact part: stainless steel |

| 5 | Peeling & Half Machine | 1 unit | 1.85 | Staihless steel+ carbon steel |

| 6 | Sorting Conveyor Belt | 1 unit | 1.1 | PVC belt/stainless steel +carbon steel frame |

| 7 | Peanut Lifter | 1 unit | 0.75 | PVC/Stainless Steel |

| 8 | Storage Tank | 1 unit | 0.15 | Material contact part: stainless steel |

| 9 | Feeder | 1 unit | 0.3 | Stainless steel |

| 10 | Colloid Grinders | 2 units | 37 | Stainless steel |

| 11 | Storage Tank | 3 units | Stainless steel | |

| 12 | Mixer (500ml) | 1 unit | 2.75 | Stainless steel |

| 13 | Discharge Machine | 1 unit | 2.25 | Stainless steel |

| 14 | Vacuum Tank | 1 unit | 4.4 | 304 stainless steel |

| 15 | Pump | 3 units | 3 | Material contact part: stainless steel |