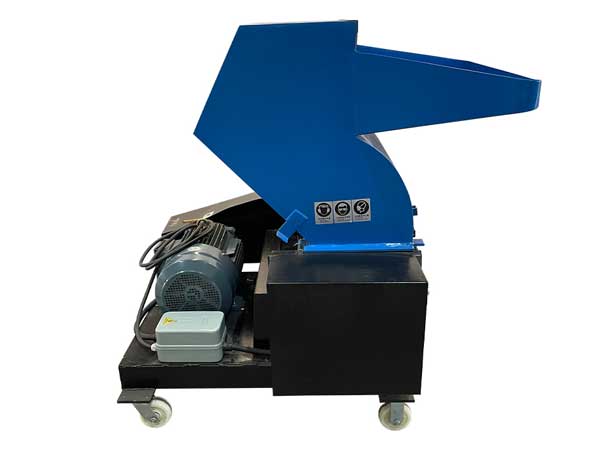

Description

Bone crusher machine is one of our key pieces of equipment in meat and bone processing, designed for efficiently crushing and grinding animal bones into small particles. Ideal for handling a wide range of fresh and frozen bones, including cow, pig, sheep, donkey, and fish bones, this machine is perfect for both food and non-food applications. Fuxun Machinery offers 8 models with processing capacities ranging from 20 to 2,000 kg/h, available in both stainless steel and carbon steel options to suit various industry needs. The bone crusher machine can be used as a standalone unit or paired with a bone paste machine for further processing. Below are more parameters for your reference.

Specifications of Bone Crusher Machine

| Model | Power (kW) | Capacity (kg/h) | Feed Hopper (mm) | Dimensions (mm) | Number of Blades | Speed (r/min) | Weight (kg) |

|---|---|---|---|---|---|---|---|

| PG-180 | 3 | 20-60 | 185×160 | 700x600x900 | 2 + 6 | 650 | 180 |

| PG-230 | 4 | 30-100 | 235×180 | 970x610x910 | 2 + 6 | 650 | 240 |

| PG-300 | 5.5 | 80-250 | 315×235 | 1150x730x1150 | 2 + 9 | 780 | 350 |

| PG-400 | 7.5 | 200-400 | 415×240 | 1150x830x1150 | 2 + 12 | 780 | 400 |

| PG-500 | 11 | 350-600 | 520×300 | 1350x950x1300 | 2 + 15 | 820 | 580 |

| PG-600 | 15 | 500-900 | 620×330 | 1350x1050x1300 | 4 + 18 | 820 | 650 |

| PG-800 | 30 | 750-2000 | 830×430 | 1550x1300x1550 | 4 + 24 | 850 | 1500 |

| PG-1000 | 37 | 2000-4000 | 1030×480 | 1800x1600x1800 | 4 + 30 | 850 | 2500 |

Applications of Bone Crushing Machine

The bone crusher machine is widely used in various industries:

- Food Processing Plants: For producing bone paste used in meatballs, sausages, and canned food. Crushed bone can be used as raw material for bone broth, bone collagen, bone peptide, and other bio-products.

- Pet Food Manufacturing: To make fine bone powder as a calcium-rich ingredient for pet feed.

- Aquatic Feed & Fishmeal Plants: Crushed bone powder serves as a nutrient source for fish and shrimp feed.

- Bone Meal & Fertilizer Production: As an organic material for producing animal-derived fertilizers.

- Gelatin and Collagen Extraction: For pretreatment of raw materials in gelatin production.

Features of Bone Crusher Machine

1. Powerful Crushing Efficiency

Fuxun’s bone crusher machine features:

- A high-torque motor and heavy-duty alloy steel blades for strong shearing and extrusion.

- Adjustable discharge mesh for both coarse and fine crushing.

- Crushes hard, dry, fresh, or frozen bones with ease.

2. Long-Life Blades and Low Maintenance

Fuxun’s alloy steel blades are heat-treated for extreme hardness and wear resistance, delivering:

- longer lifespan than standard blades.

- Consistent shearing force and low vibration.

- Simple modular replacement for fast maintenance.

3. Custom Bone and Meat Processing Solution

Fuxun offers custom bone crusher solutions:

- Adjustable hopper size, discharge outlet, and screen mesh.

- Integration with conveyors, bone paste machine, powder grinder, and more.

- Available in stainless steel (for food-grade applications) and carbon steel (for cost-effective performance).

Working Principle

The bone crusher machine works through a powerful motor-driven crushing mechanism that applies high-speed rotation, shearing, and extrusion forces to break bones into smaller granules. The main crushing chamber is equipped with high-strength alloy steel blades arranged in a specific pattern to ensure efficient and uniform crushing.

Bones are fed through the inlet hopper into the crushing chamber. As the blades rotate, bones are cut, pressed, and ground until they reach the desired size. The crushed material then passes through a replaceable sieve or mesh screen, which determines the final particle size. By changing the sieve aperture or adjusting the blade gap, users can control the output fineness to meet different production requirements.

User Guide: Common Issues & Solutions

| Problem | Possible Cause | Solution |

|---|---|---|

| Abnormal Noise | Hard impurities (metal, stones) mixed with bones; worn or loose blades. | Stop immediately, remove foreign objects, replace or sharpen blades, and tighten bolts. |

| Poor Discharge / Clogging | Wet or sticky materials block the outlet. | Clean discharge area, reduce material moisture, adjust mesh size, or optimize chamber design. |

| Motor Overload | Excessive feed rate or hard materials beyond design range. | Feed evenly, pre-treat hard materials, or use a higher-power motor. Ensure proper motor cooling. |

| Strong Vibration | Unstable foundation, worn bearings, or unbalanced blades. | Check and tighten anchor bolts, replace bearings, rebalance blades and rotary shaft. |

| Fast Blade Wear | Impurities in materials or low-quality blades. | Clean raw bones before crushing, use heat-treated alloy blades, and perform regular maintenance. |

At Fuxun Machinery, we not only provide high-performance bone crusher machines but also complete after-sales support and spare parts supply. Over time, if replacement or maintenance is needed, Fuxun offers original spare blades and accessories to keep your machine running efficiently and minimize downtime.

With our 8 models available, customizable configurations, and full after-sales service, Fuxun Machinery delivers reliable, cost-effective solutions for bone crushing and processing. Contact us today to discuss your production needs — our expert team will help you choose the most suitable model for your needs.